- Get link

- X

- Other Apps

- Get link

- X

- Other Apps

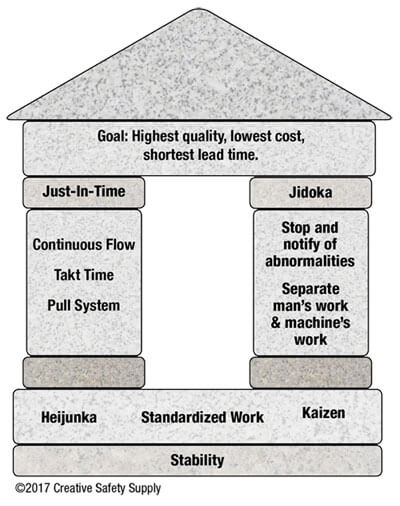

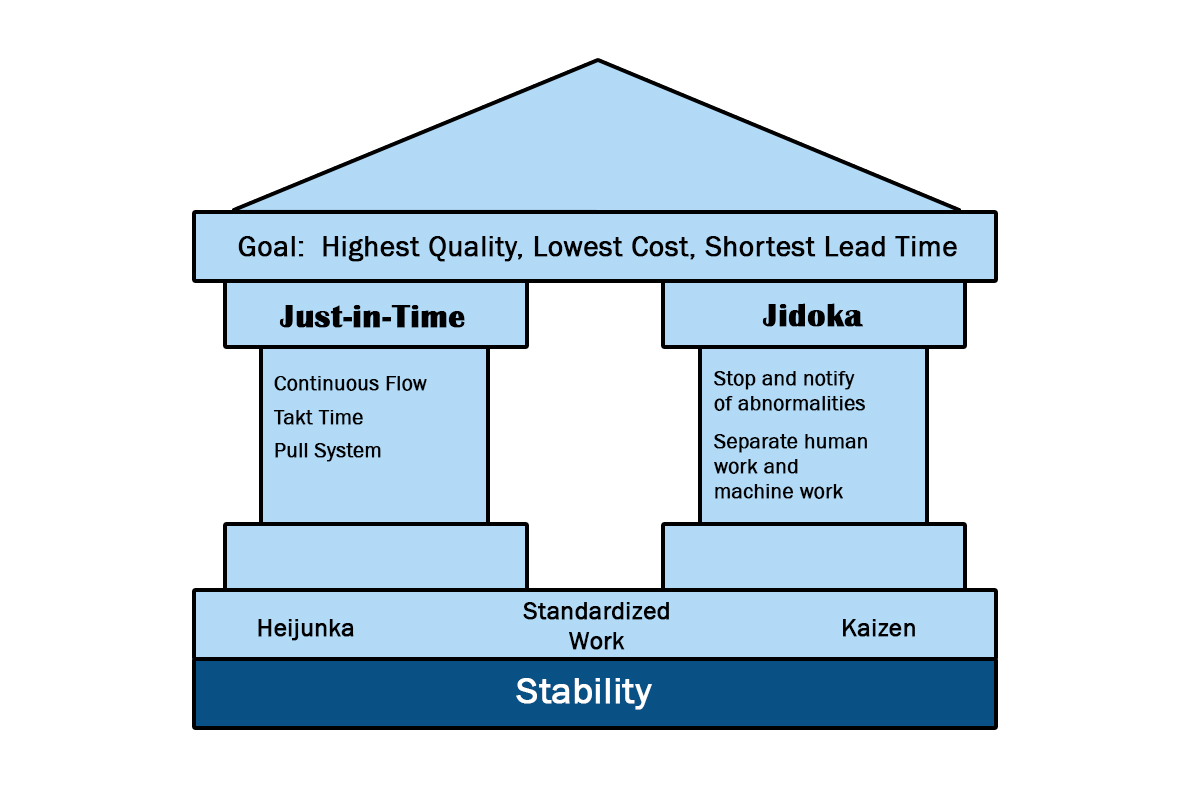

Toyotas Lean Academy is built on a Europe-wide network of experts all of whom have been working closely with Toyotas lean operations for several years. Founded on the conceptual pillars of Just-in-time and Jidoka or Automation with a Human Touch the system was first built off the approach created by the founder of Toyota Sakichi Toyoda and his son Kiichiro Toyoda.

Toyota Production System Tps Lean Manufacturing Creative Safety Supply

Toyota Production System Tps Lean Manufacturing Creative Safety Supply

The characteristics of a lean organization and supply chain are described in Lean Thinking by Womack and Dan Jones founders of the Lean Enterprise Institute and the Lean Enterprise.

Toyota lean process. Use middle managers as change agents to drive the transformation. Lean versus Toyota Production System Wat heeft het Toyota Production System met Lean te maken. Afhankelijk van uw behoefte en wensen levert het team tastbare ondersteuning variërend van LEAN assessment en training tot volledige LEAN-transformatieprogrammas.

In the early stages of lean there should be at least 80 doing and 20 training. Toyota lean manufacturing process has been a source of inspiration for many businesses for years. A proven process that works generally takes precedence over new and untested technology.

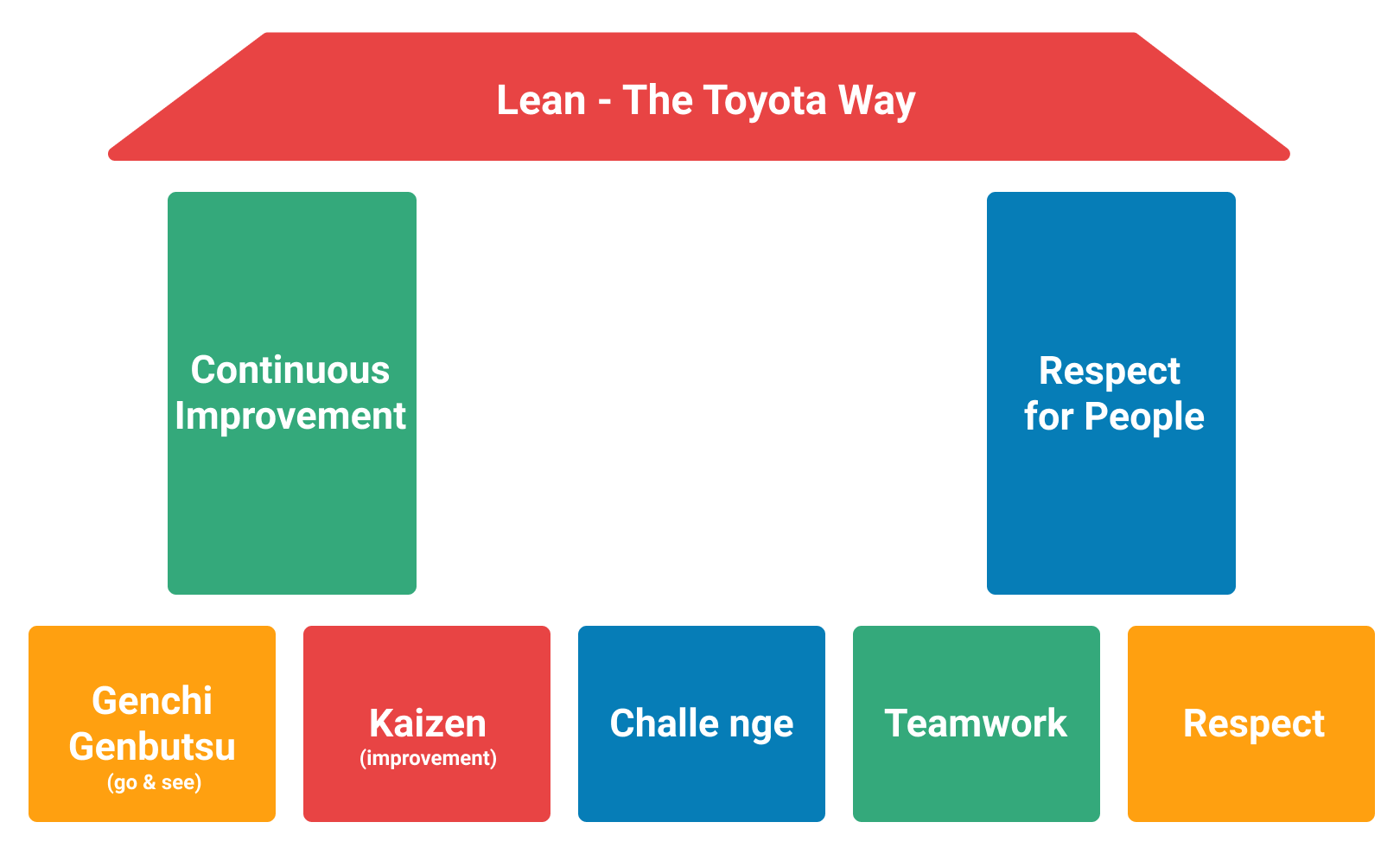

The term lean was coined to describe Toyotas business during the late 1980s by a research team headed by Jim Womack PhD at MITs International Motor Vehicle Program. The Toyota way is about learning by doing. In these difficult and highly competitive times a lean approach has never been more important.

Vaak als men het over Lean heeft dan wordt al snel de link gelegd met de automobielindustrie met name Toyota. This includes training in lean principles team building and problem solving. Nampachi Hayashi claims that TPS should have been called Toyota Process Development System Most uses of the word Lean are actually referring to TPS.

TOYOTA BUSINESS 7 Toyota has the fastest product development process in the world. The best training is training followed by immediate doing or doing followed by immediate training Use experts for getting quick results. To truly understand the power of a continuous improvement culture we again look to Toyota.

Toyota employees generate more than one million process improvement ideas annually. Reject or modify technologies that conflict with your culture or that might disrupt stability reliability and predictability. Het Toyota LEAN Academy bestaat uit een Europees netwerk van experts die allen meerdere jaren nauw betrokken zijn geweest bij LEAN processen binnen Toyota.

Depending on your requirements the team delivers valuable support ranging from lean assessment and training through to complete lean transformation programmes. Toyota became the leader in producing luxury cars when they introduced the Lexus firstly in 1989. The Lean production system is also known as the Toyota Production System TPS.

Conduct actual tests before adopting new technology in business processes manufacturing systems or products. The way they strive to increase productivity and efficiency with the aim of continuously improving business and manufacturing processes in an endless cycle. Our highly acclaimed and successful Toyota Production System TPS is admired and copied throughout the world.

Het productiesysteem van Toyota kreeg bekendheid door de successen die Toyota in Amerika haalde met het leveren van kwalitatief betere auto. It is regarded as the benchmark for manufacturing best practice. You may have missed this but.

The Toyota Production system is a major precursor of Lean Manufacturing. As you may guess the name comes from its origins in the Toyota Motor Corporation. Toyota invented the lean production known inside Toyota as Toyota Production System TPS.

Corolla was the top-selling small car in the world. TPS is based on two concepts. What Is Toyota Lean Production System.

Toyota concluded that by right-sizing machines for the actual volume needed introducing self-monitoring machines to ensure quality lining the machines up in process sequence pioneering quick setups so each machine could make small volumes of many part numbers and having each process step notify the previous step of its current needs for materials it would be possible to. Maximise Productivity and Efficiency. The philosophy is to work intelligently and eliminate waste so that only minimal inventory is needed.

The way we make vehicles is defined by the Toyota Production System TPS. It is an original manufacturing philosophy that aims to eliminate waste and achieve the best possible efficiency what is often called a lean or just-in-time system.

What Is Lean History And Early Development

Lean Production 7 Principles Of Toyota Production System Tps Lean Manufacturing

What To Learn From The Toyota Production System

What To Learn From The Toyota Production System

Toyota Production System Toyota System Business

Toyota Production System Toyota System Business

The Toyota Production System House 5stoday

The Toyota Production System House 5stoday

Toyota Production System Staff Motivation Change Management Lean Six Sigma

Toyota Production System Staff Motivation Change Management Lean Six Sigma

Toyota Production System Lean Manufacturing And Six Sigma Definitions

Toyota Production System Lean Manufacturing And Six Sigma Definitions

The Toyota Production System House Download Scientific Diagram

The Toyota Production System House Download Scientific Diagram

The Evolution Of Lean Thinking Transitioning From Lean Thinking To Flow Thinking

The Evolution Of Lean Thinking Transitioning From Lean Thinking To Flow Thinking

What Is Lean Management Definition Benefits

What Is Lean Management Definition Benefits

The Core Principles Of The Toyota Production System 37 Download Scientific Diagram

The Core Principles Of The Toyota Production System 37 Download Scientific Diagram

Lean Production Principles 7 Principles Of Toyota Lean Manufacturing Toyota Supply Chain Management

Lean Production Principles 7 Principles Of Toyota Lean Manufacturing Toyota Supply Chain Management

The Lean Agile Connection Jdriven Blog

The Lean Agile Connection Jdriven Blog

Toyota Production System Lean Process Consultants

Comments

Post a Comment